Multi test device of static motor condition evaluation

The most complete test device with a solution that adapts to every need and every pocket

Categories: Rotating machine testers - Motors and generators , Rotating machine test equipment

iTIG III is the industry's most advanced winding and electric motor static analyzer instrument. It is the ideal instrument for preventive maintenance such that the degradation of values and trend is analyzed, for the diagnosis of faulty motors and thus quickly identify and help decision making, for those who repair motors, so as to verify and certify the previous status and at the end of their work, for manufacturers of rotating machines or coils, for engineers and consultants to verify and certify installation condition, among several others. iTIG III performs more than 20 tests, low and high voltage, including high frequency impulse and partial discharge tests, all using a single portable, lightweight instrument, adaptable thanks to its modularity. User can select multiple tests to run automatically in sequence or run individual tests and easily get a full results report upon completion with just a few clicks. Voltage adjustment can be done manually or set to be done automatically. Its modularity allows the use of an additional power pack that allows tests up to 40 kV

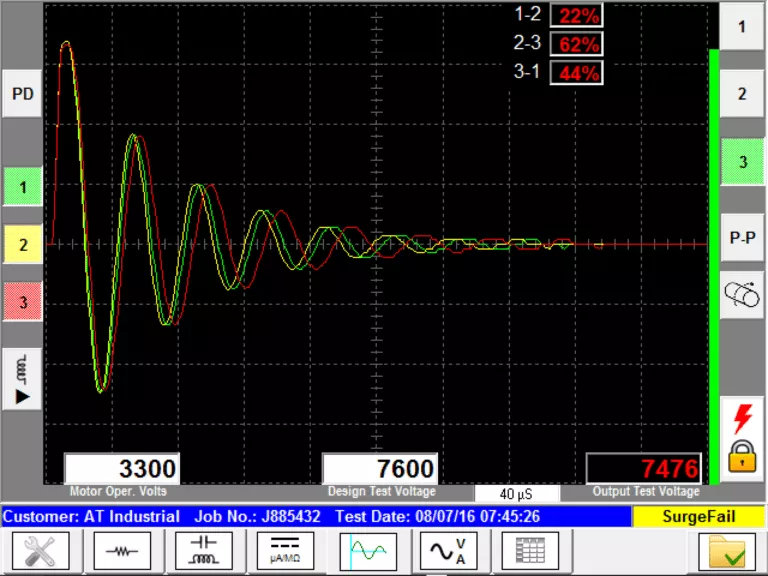

Among the featured tests, it performs surge test with pulse comparison, which includes phase-to-phase, pulse-to-pulse, and coil-to-coil comparison. Electrom developed its own system for partial discharge measurement that does not require specialists for rapid identification. This analysis includes RPDIV (start voltage), RPDEV (extinction voltage). In addition, high voltage tests in DC (hipot) can be included, which includes tensionn in user configured steps or ramp, insulation resistance (megohmmeter, polarization index, DAR dielectric absorption), resistance of windings using 4 cables (μΩ range), Capacitance (C), Inductance (L) Impedance (Z) Phase angle and RIC test or Rotor influence test. Its easy-to-use software enables easy trend analysis and reporting.

Electrom adapts to your needs and possibilities with 4 versions available A, B, C or D. The equipment is designed to accompany the growth and need of customers, iTIG III comes in different voltage levels: 4kV, 6kV, 12kV and 15kV. But by adding the additional power pack, 18kV, 24kV, 30kV and 40kV can be obtained. Each version differs according to the tests it can perform and the level of automation of tests from manual to fully automatic.

iTIG III analyzer generates fully automatic voltage pulses, controlled by embedded software, with a repetition rate of up to 50Hz, in accordance with IEEE 522. This test eliminates the dissipation of ionization that usually appears in analyzers of Low frequency. Therefore, the iTIG III detects more instances of weak insulation than low frequency impulse analyzers. Pulse-to-pulse (PP) impulse testing eliminates the need to rotate rotors by hand when testing an assembled motor. This test can also be performed on motors with normal differences in their phases, such as those with concentric windings, and on single-phase motors and coils where there are no other phases to compare with.

The differentiation in the way Electrom performs measurement of Partial Discharges (PD) comes from the fact that, as there is no internal PD, there is no need to adjust the noise/signal threshold limit as the test voltage increases, as happens in other instruments. Electrom offers two levels of PD hardware and output cables for 6kV and 15kV testing. Since there are no accessories to add thanks to its patented technology, the partial discharge test is easy and you do not need to be a specialist to perform the test and understand result. PD measurements are very sensitive and can detect insulation breaks in an electric motor earlier than impulse tests, high voltage tests, or even online tests on rotating machine monitoring. The analyzer shows in its display, when performing partial discharge measurement, the repetitive partial discharge initiation voltage (RPDIV), the extinction voltage (RPDEV) and the maximum PD levels in mV, according to IEC 61934.

iTIG III also measures leakage current with a resolution of 10 pA and a high precision measurement of up to 500 pA. The resulting insulation resistance range at 15kV is up to 30 TΩ. This means that PI polarization index tests can performed accurately on motors with a very low leakage current. A graph, can be created with the PI results of various tests. Along with testing DC HV and insulation resistance, it provides information on various insulation-to-ground faults and weaknesses. In medium and high voltage equipment, the step or ramp HV test should always be used.